Product characteristics

The quick chucks are equipped with a built-in hydraulic/pneumatic rotary cylinder, eliminating the need to install an additional rotary cylinder.

It is easy to install and enables the quick establishment of a working clamping system.

The cylinder body of the pneumatic chucks is enlarged to increase the clamping force.

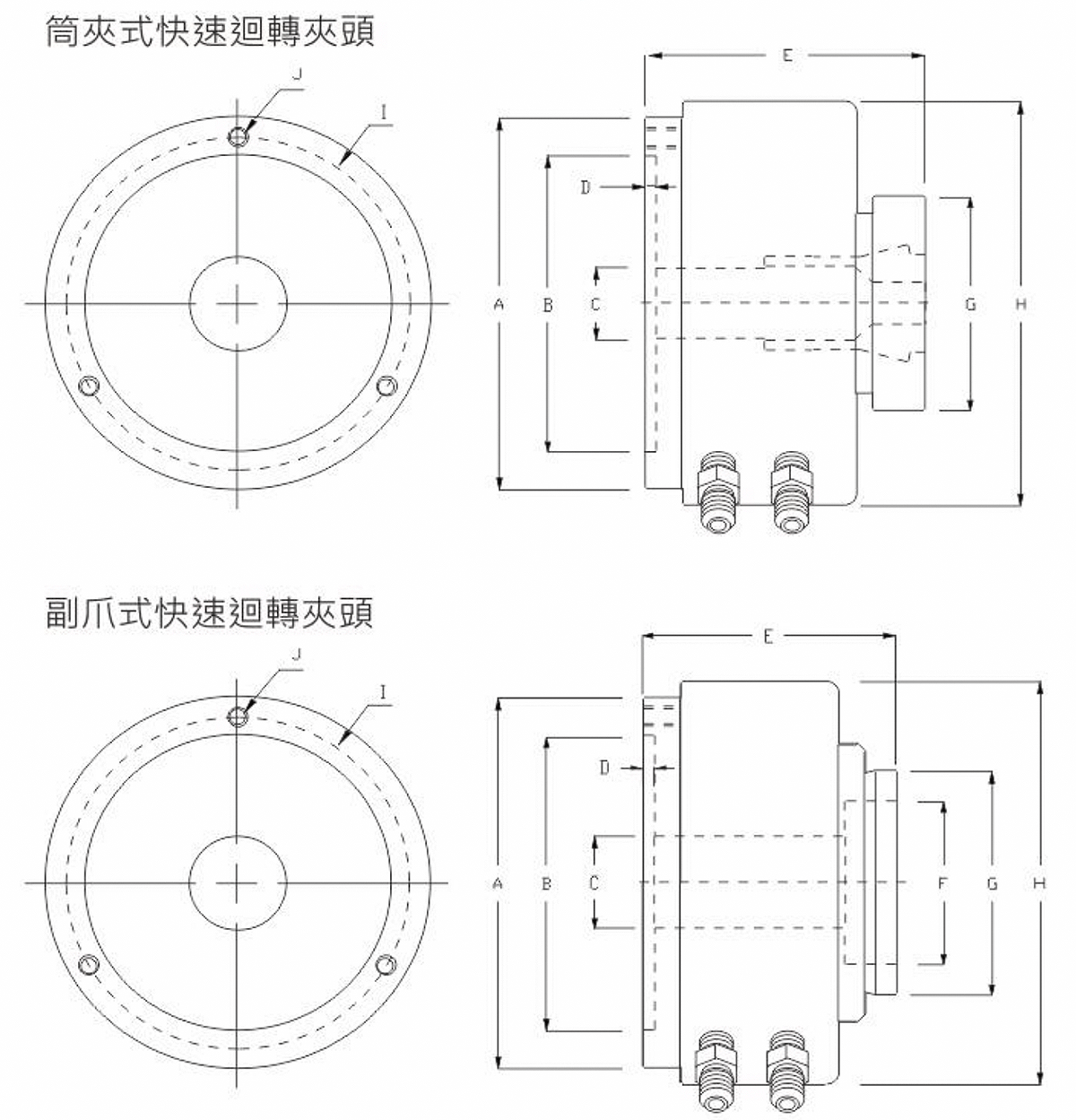

There is a design for quick replacement of collets/jaws, providing high flexibility in work.

The chucks have a design of a central through hole and can work in cooperation with the automatic feeding system.

The clamping/releasing cycle is short, resulting in a fast production speed.

It is possible to load and unload materials without shutting down the machine, leading to high production capacity.

It is suitable for retrofitting traditional lathes into automated or semi-automated ones.

It is suitable for assembling various types of special processing machinery.

The cutting fluid should not be directly sprayed towards the chucks.

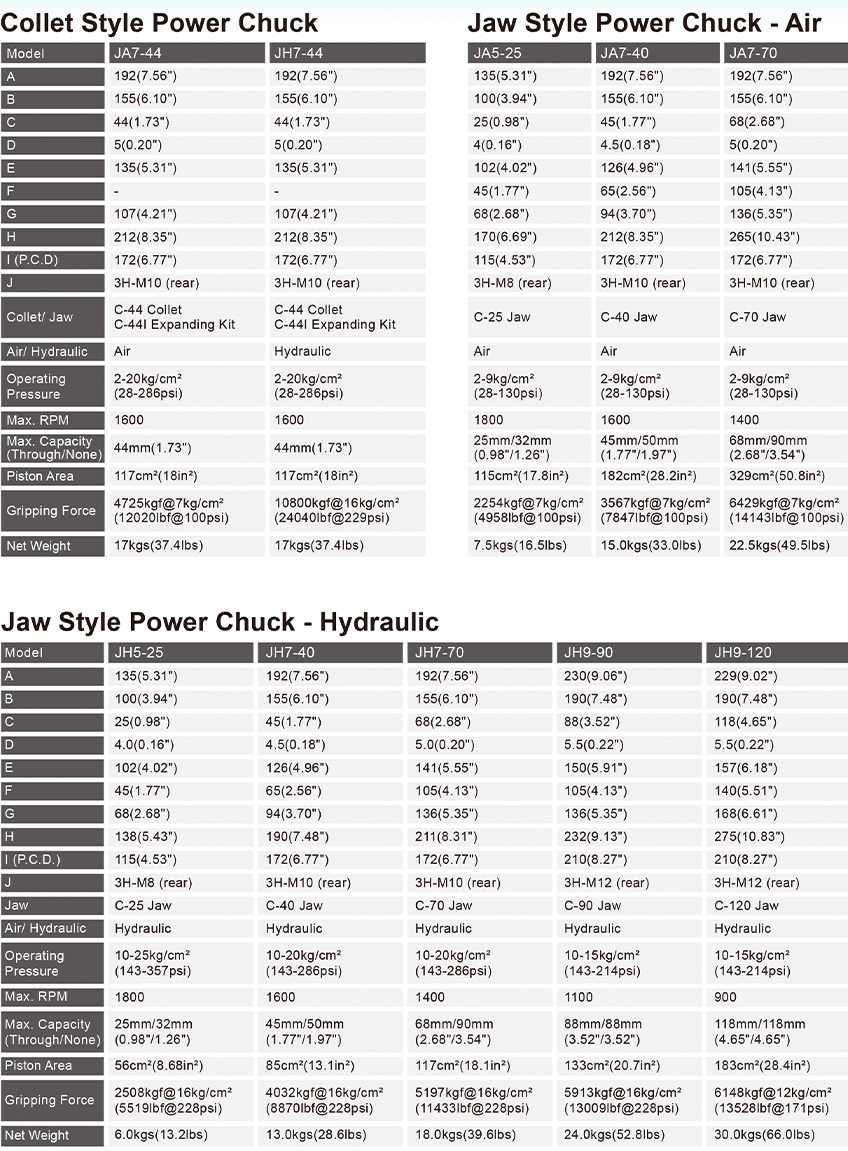

JA7-44/JH7-44 adopt a design with a 2.0-fold force increase, providing an increased clamping force.

For JA7-44/JH7-44, an internal expansion kit can be purchased for internal expansion clamping operations (refer to page 15 for the internal expansion kit).